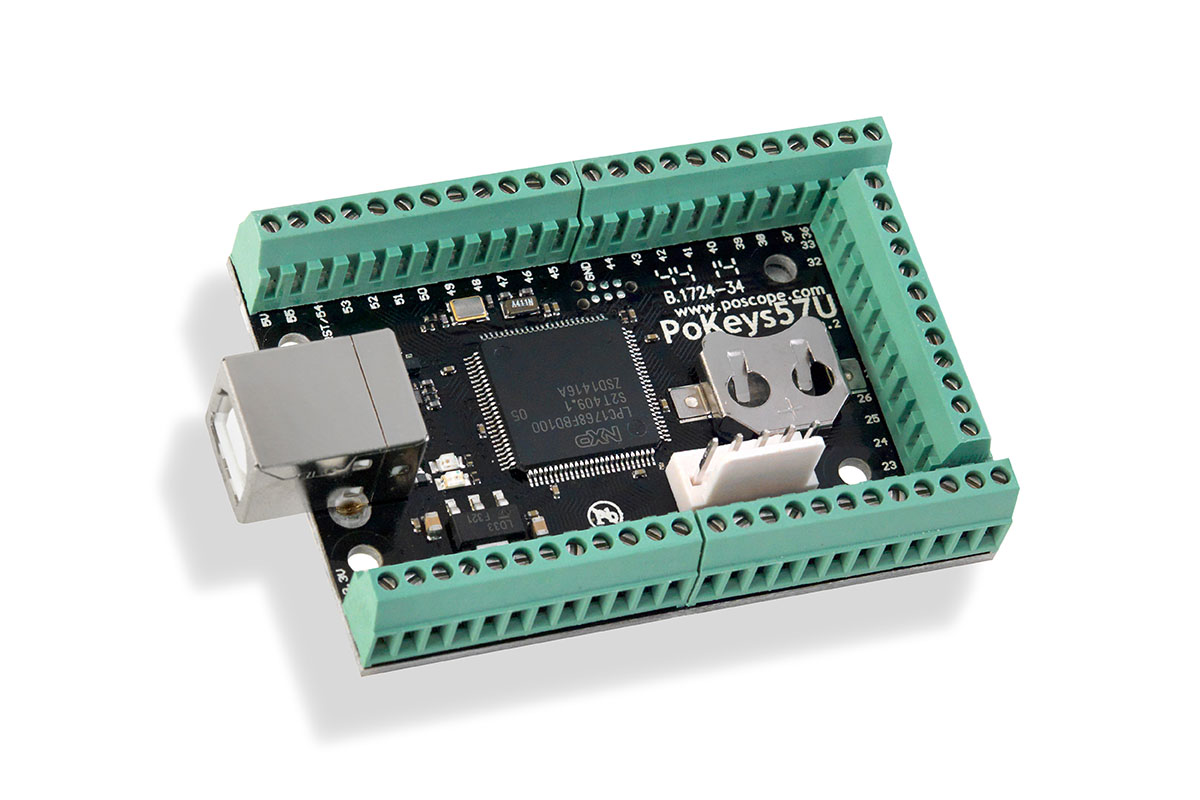

In the world of DIY projects, innovation and efficiency are key to bringing ideas to life. Whether you’re crafting a customized orchidarium, needing precise motor position control, or tackling the challenge of cutting flat cables, the tools and technologies you choose can make all the difference. One such tool, the PoKeys57U, has emerged as a game-changer for hobbyists and engineers alike, offering a versatile solution for a wide range of applications.

This article will explore the impact of the PoKeys57U, particularly in its role within a DIY orchidarium, how it can be used to control motor positions with precision, and its relevance in the specialized task of cutting flat cables. With a focus on practicality and innovation, we will dive into each of these topics, offering insights and guidance for DIY enthusiasts and professionals who are looking to enhance their projects. Whether you’re new to these concepts or an experienced builder, this guide will provide valuable information to help you integrate the PoKeys57U into your next project with confidence.

The PoKeys57U – The Heart of Your DIY Orchidarium

Creating a DIY orchidarium is a dream project for plant enthusiasts who want to cultivate a unique environment for their orchids at home. However, constructing a successful orchidarium requires precise control of multiple factors, including humidity, temperature, and lighting. This is where the PoKeys57U comes into play. Known for its exceptional flexibility and ability to integrate with various systems, the PoKeys57U can serve as the central hub for managing and automating the critical components of an orchidarium.

At its core, the PoKeys57U is a versatile I/O controller with a range of input and output capabilities. This compact device supports a variety of sensors and actuators, making it ideal for a DIY orchidarium project that demands high levels of customization. With the PoKeys57U, you can connect humidity sensors, temperature probes, lighting controls, fans, and even water pumps, ensuring that each aspect of the orchidarium functions in harmony to create the perfect environment for your plants.

Temperature and Humidity Control with PoKeys57U

Orchids are particularly sensitive to their environment, requiring very specific conditions to thrive. Temperature and humidity levels must be carefully monitored and adjusted. The PoKeys57U allows you to connect and control temperature and humidity sensors directly to your orchidarium setup. By linking these sensors to the PoKeys57U, you can continuously track the conditions within the enclosure, ensuring the environment stays within the optimal range for your orchids.

For instance, if the temperature begins to rise above the desired range, the PoKeys57U can be programmed to trigger a cooling fan or activate a ventilation system to bring the temperature back to the ideal level. Similarly, if the humidity drops too low, it can activate a misting system or a humidifier, restoring the moisture levels to keep the orchids healthy. These adjustments are crucial for creating an environment where your orchids can bloom and flourish year-round.

Automating Lighting for Optimal Growth

Another key component in any orchidarium is the lighting system. Orchids require a balance of light to encourage growth and flowering, but they are also sensitive to light intensity and duration. The PoKeys57U is equipped to manage lighting systems, whether you’re using LED grow lights or more traditional lighting setups. By integrating light sensors with the PoKeys57U, you can program the system to adjust the lighting based on the time of day, mimicking the natural light cycle and providing your orchids with the perfect amount of light throughout the year.

Furthermore, the PoKeys57U can also automate the intensity of the lights, adjusting them for different growth stages of your orchids. During the blooming phase, higher light intensity may be necessary, while a gentler light setting is required during the vegetative growth phase. The versatility of the PoKeys57U makes it the ideal solution for creating a fully automated, self-sustaining orchidarium where you don’t have to manually intervene in every aspect of orchid care.

Controlling Watering Systems

In addition to lighting, controlling water distribution is essential for maintaining a healthy orchidarium. Overwatering or underwatering can both be harmful to orchids, making a consistent watering schedule critical. With the PoKeys57U, you can integrate a water pump or drip irrigation system to automatically water your plants at set intervals. This eliminates the guesswork and ensures your orchids receive the precise amount of water they need to thrive.

By using moisture sensors connected to the PoKeys57U, you can set thresholds that trigger the watering system when the soil gets too dry. This makes it possible to automate the watering process entirely, even when you’re away for extended periods. The PoKeys57U’s ability to integrate multiple components into a cohesive system is what makes it indispensable for a DIY orchidarium setup.

Optimizing Airflow and Ventilation

Proper airflow and ventilation are vital in any orchidarium, as stagnant air can lead to mold and fungal growth, which are harmful to orchids. The PoKeys57U allows you to automate the fans and ventilation systems within the orchidarium, ensuring that air circulates properly and humidity levels remain balanced. If the humidity gets too high, the PoKeys57U can activate exhaust fans to reduce moisture, preventing mold from taking root. Conversely, if the air is too dry, it can initiate the misting system to boost humidity levels.

By monitoring and controlling airflow, the PoKeys57U ensures that your orchidarium remains a healthy and thriving environment, providing your orchids with the best chance to grow and bloom. The device’s versatility and ease of integration make it the perfect tool to handle all the nuances of managing an orchidarium.

The PoKeys57U is an essential piece of technology for anyone building a DIY orchidarium. Its ability to connect and control various sensors and devices allows you to automate temperature, humidity, lighting, watering, and ventilation systems, creating an ideal environment for orchids to flourish. By using the PoKeys57U as the central hub of your orchidarium setup, you can ensure that your plants receive the best care possible with minimal manual intervention. Whether you’re a beginner or an experienced orchid enthusiast, integrating the PoKeys57U into your project will undoubtedly elevate your DIY orchidarium to the next level.

Building Your DIY Orchidarium with PoKeys57U – Creating the Perfect Environment for Your Orchids

When it comes to building a DIY orchidarium, creating the ideal environment for your plants is crucial to their success. Orchids are sensitive and need specific conditions to thrive—temperature, humidity, light, and air circulation must all be carefully controlled. The PoKeys57U serves as the backbone of such a project, providing the perfect integration of sensors, automation, and control systems to ensure your orchidarium provides the best possible atmosphere for your plants.

Designing Your Orchidarium Layout

The first step in building a DIY orchidarium is designing the layout. Typically, an orchidarium will have a glass enclosure, either a tank or a cabinet, which allows you to control the internal environment while providing adequate light. The PoKeys57U can be integrated into this setup from the start, helping to streamline the design and automate complex tasks. It connects to a range of sensors and actuators, making it an ideal choice for maintaining optimal temperature and humidity levels within your orchidarium.

In your design, think about the placement of the PoKeys57U and its connected devices. Positioning temperature and humidity sensors near the top and bottom of the enclosure can provide valuable data about air circulation and whether there are areas in your orchidarium that may be too hot or too cool. This data will be key for controlling fans, heaters, or misting systems to maintain the perfect conditions for your orchids. The PoKeys57U’s flexible design lets you place it wherever it is most convenient, while still effectively managing the systems inside the orchidarium.

Temperature and Humidity Control: The PoKeys57U Advantage

For most orchids, maintaining the right temperature and humidity levels is one of the most critical aspects of orchid care. The PoKeys57U excels in this area, as it can easily interface with temperature and humidity sensors to ensure these factors remain stable. When connected to temperature sensors, the PoKeys57U continuously monitors fluctuations in the environment and can adjust heating or cooling devices accordingly. For example, if the temperature rises beyond the desired range, the PoKeys57U can trigger a fan or ventilation system to cool things down. This automated process helps to avoid sudden temperature swings, which can stress the orchids and inhibit their growth.

Humidity is equally important. Orchids thrive in high humidity environments, and maintaining consistent moisture levels is necessary for their health. By incorporating humidity sensors into your DIY orchidarium, you can have the PoKeys57U monitor moisture levels in real time. If the humidity falls below a set threshold, it will activate a misting system or a humidifier to keep the air moisture levels in check. This ability to control both temperature and humidity via automation not only makes the care of your orchids more efficient but ensures that the plants receive precisely the conditions they need for optimal growth.

Lighting Control with PoKeys57U

Lighting is another essential factor in the growth of orchids. They require a balanced light cycle that mimics natural sunlight to promote blooming. Different orchid species have varying light requirements, so understanding the needs of the specific orchids in your care is important. With the PoKeys57U, you can take control of your lighting system, ensuring that your orchids receive the right amount of light based on the time of day or growth stage.

One of the advantages of using the PoKeys57U for lighting control is its flexibility. Whether you’re using LED grow lights, fluorescent lights, or another type of lighting, the PoKeys57U can be programmed to manage the light intensity and schedule. For instance, you can set it to gradually increase the light intensity in the morning and dim it in the evening, simulating a natural day-night cycle. Furthermore, with light sensors integrated into the system, you can adjust the lighting based on the current light levels in the room, ensuring that your orchids aren’t subjected to too much or too little light.

This adaptability is key to providing the right lighting for your orchids. You can also set up specific light schedules depending on the growth phase of your orchids—higher light levels during the blooming season, for example, or reduced light intensity when the plants are dormant. The PoKeys57U helps to ensure your orchids receive the perfect light for every stage of their life cycle.

Airflow and Ventilation: The Role of PoKeys57U

Good airflow is essential in an orchidarium to prevent the build-up of humidity that can cause mold or mildew. Orchids require a stable environment where air can circulate freely, and the PoKeys57U can help ensure this happens automatically. By connecting the PoKeys57U to fans or ventilation systems, you can control airflow based on temperature and humidity readings.

For example, if humidity levels get too high, the PoKeys57U can activate the exhaust fan to expel excess moisture from the orchidarium. On the other hand, if the temperature rises too much, it can trigger a ventilation system to cool down the space. With integrated air circulation control, the PoKeys57U helps to maintain balanced air quality within your orchidarium. This prevents the development of fungal growth and ensures that your orchids have the oxygen they need to thrive.

By automating these systems, the PoKeys57U frees you from the need to manually adjust fans and vents, ensuring that your orchids enjoy a consistent and healthy environment, even when you’re not around to monitor it constantly.

Watering Systems: PoKeys57U at Your Service

Watering is one of the most essential aspects of maintaining orchids, but it is also one of the most delicate. Orchids require a delicate balance of moisture, and overwatering or underwatering can quickly lead to root rot or dehydration. With the PoKeys57U, you can automate your watering system, ensuring your orchids receive just the right amount of water at the right time.

By connecting moisture sensors to the PoKeys57U, you can program it to detect when the soil becomes too dry and trigger the watering system to activate. This ensures that your orchids are never left without water, even if you forget to check on them regularly. The PoKeys57U can control a drip irrigation system, misting system, or water pump, depending on the setup you choose. With automated watering control, you can prevent the risks of overwatering and underwatering while providing your orchids with the care they need.

The PoKeys57U is the perfect companion for creating a DIY orchidarium that ensures your orchids flourish in the ideal environment. From regulating temperature and humidity to controlling lighting, airflow, and watering systems, the PoKeys57U integrates seamlessly into every aspect of orchid care. This all-in-one solution simplifies the process of building and maintaining an orchidarium, allowing you to automate everything from environmental conditions to watering schedules. With the PoKeys57U at the heart of your orchidarium, you can focus on the joy of growing orchids, knowing that the technology will take care of the details. Whether you’re a novice or a seasoned grower, the PoKeys57U will help elevate your orchidarium to new heights.

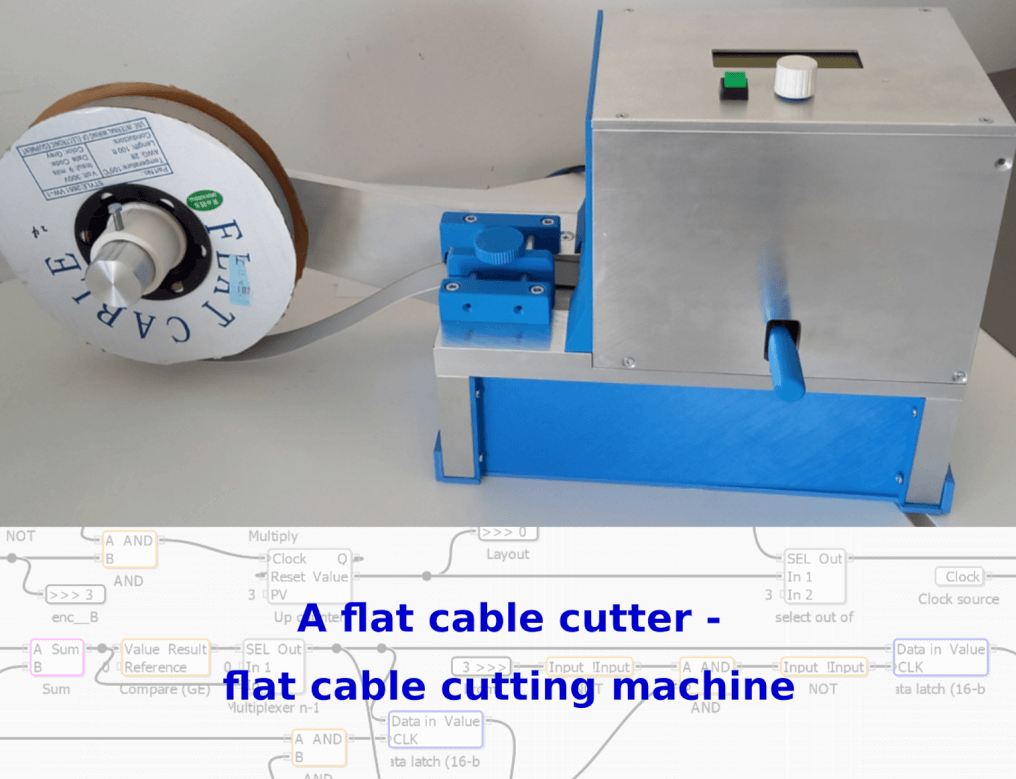

Precision Cutting with the PoKeys57U and Flat Cable Cutter

In the world of DIY electronics, precision is essential, and when it comes to tasks like cutting flat cables, having the right tools at your disposal can make all the difference. The PoKeys57U, with its ability to interface with a variety of input and output devices, plays a vital role in ensuring that even specialized tasks like cutting flat cables are executed with maximum accuracy and efficiency. When paired with a flat cable cutter, the PoKeys57U enhances the precision of the entire cutting process, making it an indispensable part of any DIY project that involves cables and wiring.

Understanding Flat Cable Cutting Needs

Flat cables, often used for applications like computer connections, electronics projects, and in environments where space is tight, require careful handling. Unlike round cables, flat cables are delicate and can easily be damaged if not cut correctly. Whether you’re working with ribbon cables, flat-flex cables, or any other type of flat cable, a flat cable cutter is specifically designed to handle these cables with the necessary precision.

Without the right tools, attempting to cut flat cables can lead to fraying or damaging the internal wires, which can render the cables useless. Manual cutting methods, such as using scissors or traditional wire cutters, may result in uneven cuts, causing the cable to function improperly. For this reason, it’s crucial to have the right equipment and technology to carry out the task with the required precision.

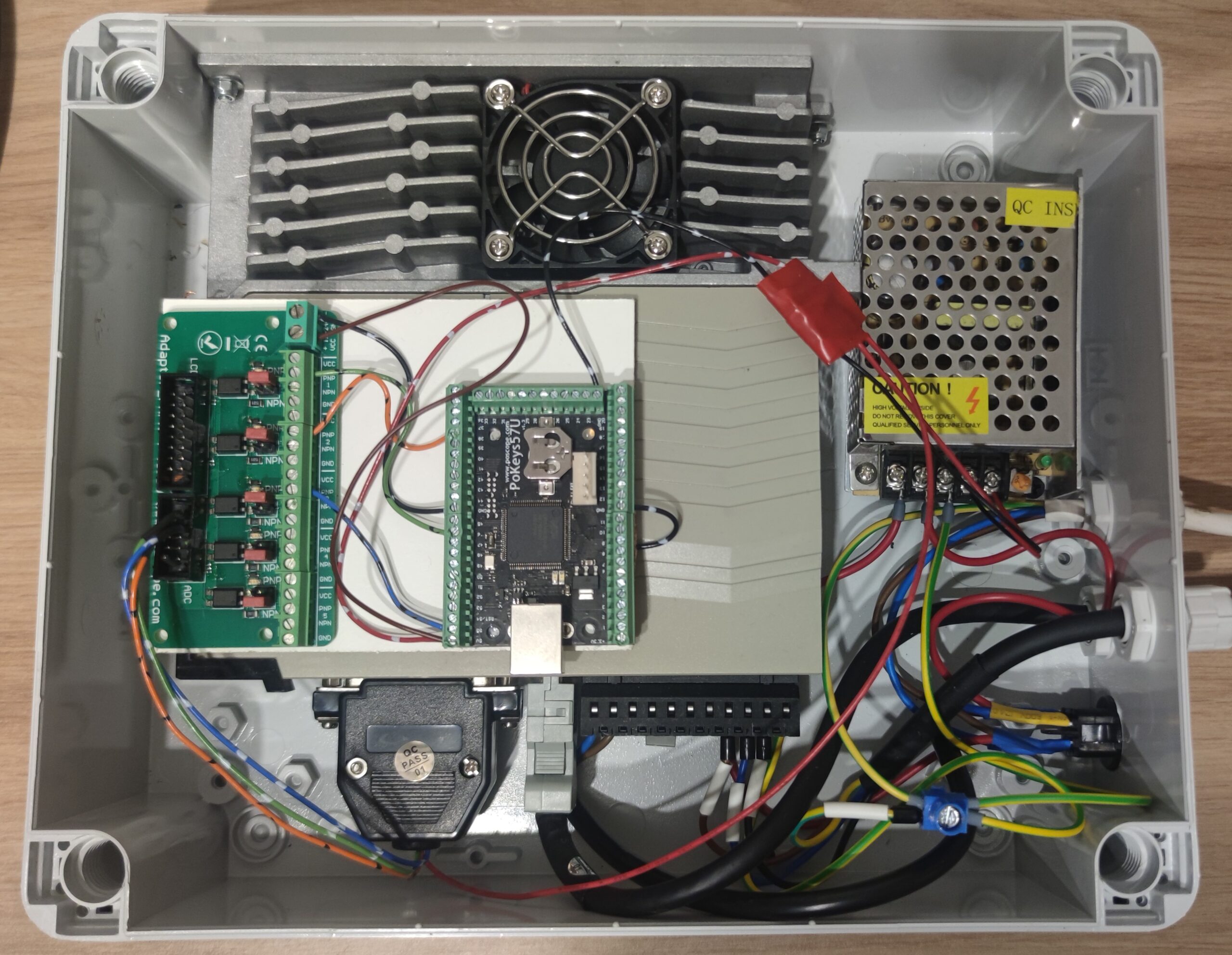

PoKeys57U and Automated Cutting Systems

The PoKeys57U is equipped to handle a variety of mechanical systems, including those used for cutting flat cables. When combined with a flat cable cutter, the PoKeys57U can automate the cutting process, allowing for more consistent and reliable results. Whether you’re cutting cables to specific lengths for use in circuit boards, wiring installations, or other electronic devices, the PoKeys57U ensures that each cut is made accurately and efficiently, minimizing the risk of errors.

By integrating the PoKeys57U into your setup, you can easily control the positioning and movement of the flat cable cutter. For example, you can program the PoKeys57U to recognize specific lengths of cable, activating the cutter to make cuts automatically without any manual intervention. The precision and speed offered by the PoKeys57U significantly improve the cutting process, especially in scenarios where multiple cuts need to be made in quick succession.

Adjustable Cutting Lengths and Precise Control

One of the standout features of using the PoKeys57U in conjunction with a flat cable cutter is its ability to adjust the cutting lengths automatically. This is particularly useful for DIY projects that require multiple cables of the same size, such as when you need to wire a circuit board or create a set of uniform connections. The PoKeys57U can be programmed to recognize and adjust for different cable lengths based on pre-set parameters.

For example, if you are working on a project that requires cutting multiple pieces of cable, the PoKeys57U can be set to cut each piece to a specific length, ensuring that all cables are uniform. The device can also allow for fine adjustments, ensuring that even the smallest increments of measurement are handled with precision. With this level of control, you can eliminate the guesswork and achieve cuts that are perfectly suited to your needs.

Efficiency in Repetitive Cable Cutting

If you’re working on a large-scale project that requires repetitive cable cutting, the PoKeys57U offers a significant advantage in terms of speed and efficiency. Rather than manually measuring and cutting each piece of cable, the PoKeys57U can automate the entire process. This is particularly helpful in projects where dozens or even hundreds of cables need to be cut to the same specifications.

With a flat cable cutter integrated into the PoKeys57U system, the cutter can make quick, precise cuts without the need for constant manual intervention. Once the cutting parameters are set, the system can run autonomously, reducing both the time and effort required to complete the task. This efficiency can free up valuable time for other aspects of your project, allowing you to focus on the more creative or complex parts of the build.

Safety Features of the PoKeys57U in Cable Cutting

When it comes to cutting flat cables, safety is a key consideration. Traditional methods of cable cutting often involve handling sharp tools, which can lead to injuries if not used carefully. The PoKeys57U, when integrated with a flat cable cutter, can add an extra layer of safety by allowing for automated operation. With the system running on pre-programmed commands, there is no need to physically handle the cutting tool during the process, reducing the risk of accidents.

Furthermore, the PoKeys57U can be equipped with safety sensors that detect when the cutting tool is misaligned or when the cable is improperly positioned. In such cases, the system can automatically stop the cutting process to prevent damage to both the cable and the equipment. This automated safety feature ensures that the cutting operation proceeds smoothly without the risk of mishaps.

Integrating the PoKeys57U into Your DIY Workspace

In a DIY workspace, having a system that can handle cable cutting automatically is a valuable asset. The PoKeys57U can easily be integrated into your workspace, either as a standalone device or as part of a larger automation system. By connecting the PoKeys57U to a flat cable cutter and other necessary equipment, you can create a streamlined workflow that minimizes manual labor and maximizes precision.

The device’s flexibility allows it to work with various types of cutters and systems, meaning you can use it with different models of flat cable cutters depending on your specific needs. Whether you’re working on electronics repairs, custom wiring, or creating cables for a larger automation project, the PoKeys57U offers the control and accuracy needed to ensure the cutting process is both quick and precise.

The PoKeys57U, when integrated with a flat cable cutter, offers a reliable, precise, and efficient solution for cable cutting tasks in DIY projects. By automating the process, the PoKeys57U eliminates the risk of uneven or inaccurate cuts, ensuring that flat cables are consistently cut to the correct length for any application. Whether you’re working on a small-scale electronics project or a larger, more complex system, the PoKeys57U enhances the cutting process, making it faster, safer, and more efficient. By adding this technology to your DIY workspace, you ensure that your cable-cutting tasks are executed with the utmost precision, making it an essential tool for any serious electronics enthusiast or DIYer.

Mastering Motor Position Control with PoKeys57U

Motor position control is a critical aspect of many DIY automation projects, robotics, and industrial applications. Whether you’re working on a robotic arm, CNC machine, or any other system requiring precise movement, achieving accurate and smooth motor control can be a challenge. The PoKeys57U, with its extensive range of I/O capabilities and flexibility, has emerged as a go-to solution for motor position control. It can be integrated into a variety of motor systems, ensuring that movements are both precise and repeatable—key factors in the success of any automation project.

Understanding the Importance of Motor Position Control

Motor position control refers to the process of controlling the exact position of a motor’s shaft within a system. In applications like robotics, CNC machining, and 3D printing, precise motor control is essential for ensuring that parts are positioned accurately and that movements occur smoothly and predictably. Without accurate position control, a system can suffer from issues such as mechanical errors, missed steps, or incorrect movements, leading to costly mistakes and inefficiencies.

For motor systems to perform optimally, they require feedback loops that allow the controller to continuously monitor and adjust the motor’s position. This is where the PoKeys57U shines, offering a powerful and customizable solution for motor position control. By connecting the PoKeys57U to encoders, motors, and other feedback systems, you can create a precise control system that delivers high accuracy and reliability.

Integrating PoKeys57U with Stepper Motors and Servo Motors

There are many types of motors that require position control, but stepper motors and servo motors are among the most commonly used in DIY automation projects. Both of these motors rely on feedback systems to maintain precise positioning, and the PoKeys57U is fully equipped to handle these needs.

Stepper motors, for instance, are widely used in applications where incremental movements are required. They work by dividing a full rotation into a series of discrete steps. The PoKeys57U can be used to control stepper motors with great precision, providing the necessary signals to each stepper coil to achieve the desired movement. Using the PoKeys57U in a stepper motor system allows you to fine-tune the motor’s rotation, adjusting for any necessary microsteps to improve the smoothness and accuracy of the motion.

Servo motors, on the other hand, offer continuous rotation but are typically used where precise positioning and torque control are required. The PoKeys57U can work with servos by providing PWM (pulse-width modulation) signals to adjust the motor’s position. With this ability, the PoKeys57U ensures that servo motors move to the exact location in response to specific commands, ideal for applications such as robotic arms, antenna positioning, or camera gimbals.

Feedback and Closed-Loop Control Systems

A key aspect of motor position control is the feedback system, which provides the controller with real-time data about the motor’s position. The PoKeys57U is compatible with a variety of feedback devices, such as rotary encoders and potentiometers, which can be used to monitor the motor’s position. By incorporating these feedback devices, you can create a closed-loop control system, where the PoKeys57U constantly compares the motor’s actual position with the desired position and makes adjustments as needed.

In a typical setup, a rotary encoder will provide the PoKeys57U with data on the motor’s current position. If the motor moves out of alignment, the PoKeys57U can correct the motor’s movement by adjusting the signals sent to the motor driver. This ensures that the system remains highly accurate, even if external forces or variations in load impact the motor’s movement.

Closed-loop systems using PoKeys57U are especially useful in applications that require high precision, such as CNC milling machines, 3D printers, and pick-and-place robots. With feedback control in place, the motor will always return to the correct position, preventing errors or drift over time. This is crucial when working on complex, high-precision projects that rely on accurate motor movements.

Fine-Tuning and Customizing Motor Movements

One of the standout features of the PoKeys57U is its ability to offer fine-tuning and customization for motor movements. The device can be programmed to control motor speeds, acceleration rates, and even the duration of movements, all of which are vital for achieving smooth, precise motions in your project. Whether you need to slow down a motor for delicate movements or speed it up for high-throughput tasks, the PoKeys57U provides the tools to tailor motor control to your exact specifications.

Moreover, you can customize motor movements based on external factors. For example, in robotic systems, you may want to alter motor speeds or adjust the position based on sensor readings or environmental conditions. With the PoKeys57U, you can program these responses, making the motor position control more adaptive and intelligent.

The ability to fine-tune motor movements is also beneficial when you’re working on complex trajectories, such as those required in CNC machines or robotic arms. By adjusting the motor’s path, acceleration, and deceleration rates, you can prevent jerky movements and achieve smooth, continuous motion, which is critical for high-quality results.

PoKeys57U in Multi-Axis Position Control Systems

For more complex systems, such as CNC machines or robotic arms that require multi-axis control, the PoKeys57U offers the flexibility to control multiple motors simultaneously. Using its various I/O ports, the PoKeys57U can be configured to handle motor position control across multiple axes, allowing for intricate, coordinated movements.

In a multi-axis system, the PoKeys57U can synchronize the movement of each motor to ensure that all axes are moving as required. This is essential for applications like milling, where the position of the tool head must be coordinated along the X, Y, and Z axes with extreme precision. Similarly, robotic arms require synchronized motor movements to ensure the arm follows the correct path and reaches the right position at each stage of the task.

By using the PoKeys57U, you can create a highly efficient multi-axis motor control system, reducing the need for manual adjustments and ensuring precise control over each motor’s position. This level of coordination and precision is essential for tasks in industries ranging from manufacturing to advanced robotics.

Motor position control is at the heart of many DIY and industrial automation projects, and the PoKeys57U provides the flexibility, accuracy, and ease of integration needed to achieve precise control over motors. Whether you’re working with stepper motors, servo motors, or multi-axis systems, the PoKeys57U offers the tools to automate and fine-tune motor movements to an unprecedented level of accuracy. By leveraging feedback devices like encoders and creating a closed-loop system, the PoKeys57U ensures that your motors operate with precision, reducing errors and increasing the reliability of your projects. Whether you’re building a robotic arm, a CNC machine, or another automation system, the PoKeys57U enables you to master motor position control with ease, taking your DIY projects to the next level of sophistication and accuracy.

The Power of PoKeys57U in DIY Automation Projects

The PoKeys57U stands out as a powerful and versatile tool in the realm of DIY automation. Its flexibility and ability to integrate with various systems make it the ideal solution for a wide range of projects, from creating a perfectly controlled DIY orchidarium to automating the precise cutting of flat cables or mastering complex motor position control. With its robust I/O capabilities, the PoKeys57U not only simplifies but elevates the process of managing environmental systems, controlling machinery, and automating tasks.

When it comes to a DIY orchidarium, the PoKeys57U ensures that the perfect conditions are maintained for your orchids to thrive, offering seamless control over temperature, humidity, lighting, and more. In projects involving flat cable cutting, the PoKeys57U automates the process, providing precision and speed that is impossible to achieve with manual tools alone. And for motor position control, the PoKeys57U’s integration with stepper and servo motors ensures that even the most intricate movements are executed with accuracy and consistency, all while allowing for fine-tuning and customization.

Ultimately, the PoKeys57U empowers makers and engineers to push the boundaries of their DIY projects, enabling them to create highly efficient, precise, and automated systems that would otherwise be challenging to achieve. Whether you’re a hobbyist looking to take your automation projects to the next level, or an industry professional aiming to streamline your processes, the PoKeys57U provides the essential foundation for creating reliable and sophisticated systems. With its support for automation, monitoring, and control, it is the ideal solution for anyone looking to enhance their DIY workspace with cutting-edge technology and efficiency.